Equipment Listing

as of 8/1/2008Turning Machine Centers

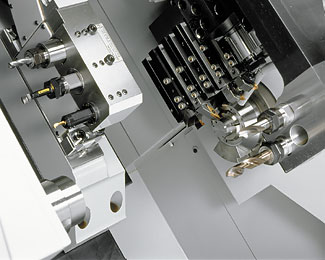

Mori Seiki NZ2000T2Y2

Multi-axis turning center with two spindles, two turrets and two Y-axis.

Mori Seiki ZT1500YB

The ZT1500YB is a compact 65 mm dia. (2.5 in.) "large bar work"

machine, the most compact in the world of its kind with a maximum

8-inch class bar work capacity. To ensure the machine would

have unrivalled bar work capacity as well as high output, high

rigidity, and a compact size, the spindle's built-in motor was

designed from the ground up. The turret comes equipped with

quick-change specifications as a standard feature* which allows

rapid exchange of tools in each holder to match the type of

machining that is being done. Additionally, the Y-axis travel for

the upper turret is set to ±50 mm (±2.0 in.) – the largest in its

class. The ZT Series of dual-processing turning centers

features a two-spindle/two turret machine design. Two spindle stocks

with the same capacity are placed opposite each other, and turrets

that can be moved along the X- and Z- axis are located above and

below the spindle center. In order to deliver optimum process

balance in a self-contained two-step process, workpieces on either

of the spindles can be accessed from either of the turrets, on top

or below.

Mori Seiki CL2000BT

Mori Seiki SL-0F

Mori Seiki SL-0F

with 3 Jaw Chuck, Max. Swing Over Bed 7.5" Max. Length 7.5"

Mori Seiki SL-00

with 3 Jaw Chuck, CPS-16 LNS

Collet Chuck, LNS Super Hydrobar Type HYS 6.32 HS-5.2 Bar Feed for

1/16"-1 1/4" Dia. Bars, Tailstock

Mori Seiki SL-25

with Tailstock AD 65 Riken Collet Chuck, 10"-3 Jaw Chuck CNC Hydrobar Feed for 3/4"-2 1/2" Bars, Max. Swing Over Bed and Door/Cross Slide 20"/13.7" and Max. Length 24.6"

Mori Seiki SL-2

with AD 65 Collet Chuck, CNC Hydrobar Feed for 3/4"-2 1/2" Bars, Max. Swing Over Bed and Door/Cross Slide 20"/13.7" and Max. Length 16"

Eurotech 710 SLL

Fanuc 18TT 7 Axis Control •

40 to 4,000 RPM Spindles • 9" Color Monitor

35 Horsepower Main Spindle • Full Keyboard • 10

Horsepower Sub-spindle

Graphic Cutting Display • Collet System for Bar Work •

Auto Part Transfer

12 Station upper Turret • 45° Extra Rigid Bed Design •

12 Station Lower Turret

2 Spindles • 2 Turrets • 0.7 Second/Station Indexing

• 7 Axis Simultaneous Mach.

180° Index - 1.83 Seconds • Main Spindle First

Operation • 787 IPM Z-Axis & B-Axis

Sub-spindle Secondary Op. • 787 IPM X-Axis • 32-bit

CPU High-Speed CNC

Programmable Parts Catcher • Simultaneous Operations •

Double Tool Probe

Milling Machine Centers

Mori Seiki DuraVertical (2)

(2)

With its sturdiness and simplicity and its high flexibility and versatility,

the DuraVertical offers the superior cost performance of stable, reliable operation and high-precision,

high-quality machining. Based on the concept of highest-level basic performance and reliability,

it provides powerful support for our customers' machining, to produce precisely what you need at

exceptional value.

Mori Seiki Duracenter (2)

By using DDS (Direct Drive Spindle) motor gearless technology, the Duracenter5 ensures that the full power of the spindle is applied at all speeds. The No. 40 taper spindle reaches its maximum speed of 12,000 rpm in 1.1 seconds. The automatic tool changer also increases productivity with a tool-to-tool time of 1.0 second.

The Duracenter 5 features a rapid traverse rate of 945 ipm on all axes. The vertical machining center handles work pieces weighing up to 1,760 lbs. on its 43.3 in. by 23.6 in. worktable.

Okuma MC-V4020 (3)

Miyano MTV-T350

Miyano MTV-T350

Kitamura Mycenter H400

Fanuc 15mb control • 10,000 RPM Spindle • Tool Life

Management

100 Tool attached (CT40) • Coordinate System Rotation G68

2 Station APC • Auto Corner Override • Work

Coordinate Offset 54 PCs

Tool Offset 200 PCs • Shower & Wash Coolant • 4th

Axis Rotary Table

Coolant thru Spindle • Registerable Programs 200 PCs •

Caterpillar Chip Conveyor

Helical Interpolation SDP G60 •

Spindle Oil Chiller • High Speed Remote Buffer

Fanuc Drill Mate (2)

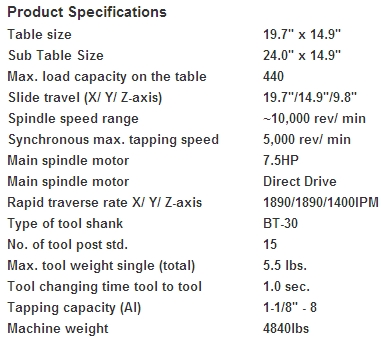

Model T10 with Fanuc OMC CNC Control System with 25.6"x14.9" Table Size, Work Envelope is 19.7"x14.9"x11.8", 10 Tool Carousel

Mori - Seiki MV-JR

Vertical Maching Center with 35.4"x17.7" Table size, Work Envelope is 22"x16.1"x18.1",

20 Tool Carousel

Mori - Seiki MV-45

Vertical Maching Center with 43.3"x17.7" Table size, Work Envelope is 30"x17.7"x19",

20 Tool Carousel

Mori Seiki MT-1

Multi-Turn Lathe with Twin Spindles, Twin Turrets and Milling Head; 40-Tool Capacity

Mori Seiki MT-2

Multi-Turn Lathe with Twin Spindles, Twin Turrets and Milling Head; 60-Tool Capacity

Swiss Machine Centers

Citizen L-32

Tsugami BE-19

Tsugami BE-19

Citizen F-20

CNC Swiss Automatic with Fanuc 0TB Controls. Two Turrets with 5 Tools Each

and Automatic Bar Feeder

Citizen L-25

100% Servo Equipped • 9" Monitor • 6 Axis Control

2 Spindles • 7.5 Horsepower Spindle • 17 Tool Capacity

4 Live Tools • Max. Dia. 1.0" • Length Per Chucking 10.0"

8,000 RPM Main Spindle • 6,000 RPM Sub-spindle

Star VNC-20

CNC Swiss Automatic with Fanuc 3TC Controls. Two Turrets with 6 Tools Each

and LNS Hydrobar Feeder

Mori Seiki MT-1

Multi-Turn Lathe with Twin Spindles, Twin Turrets and Milling Head; 40-Tool Capacity

Mori Seiki MT-2

Multi-Turn Lathe with Twin Spindles, Twin Turrets and Milling Head; 60-Tool Capacity

CNC Electro Discharge Machining (EDM)

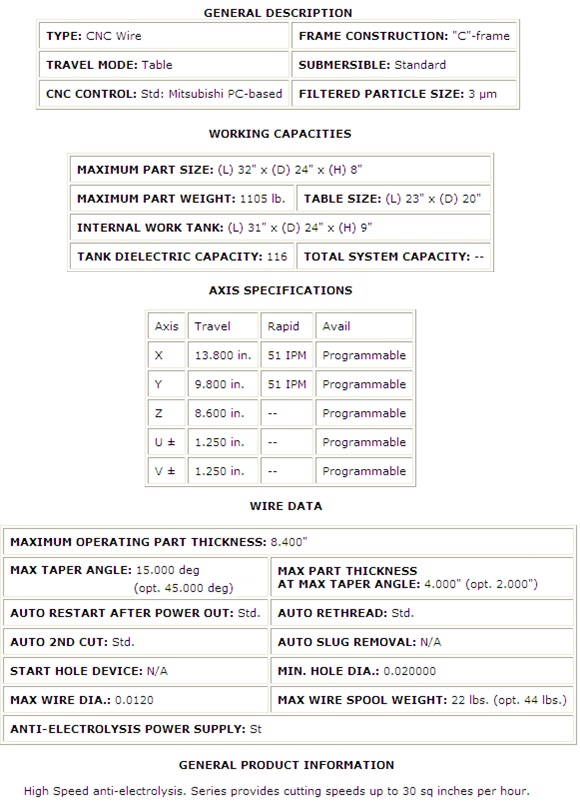

Mitsubishi EDM FA10S

Mitsubishi EDM DWC90HA

General Specifications:

Max workpiece Dimensions (W x D x H)...... 350mm x 400mm x 160mm

13.78in x 15.75in x 6.30in

Maximum workpiece weight ................. 175 kg

386 lbs

Table Dimensions ......................... 420mm x 510mm

16.54in x 20.08in

Machining Range (X x Y) .................. 250mm x 300mm

9.84in x 11.81in

Table Fast-feed Speed .................... 1300 mm/min

51.18 in/min

Wire Diameter ............................ 0.03mm ~ 0.33mm

0.004in ~ 0.013in

Max. Wire-feed Rate ...................... 250 mm/sec

9.84 in/sec

Wire Tension ............................. 200 g ~ 2500 g

0.44 lbs ~ 55 lbs

Surface Grinding

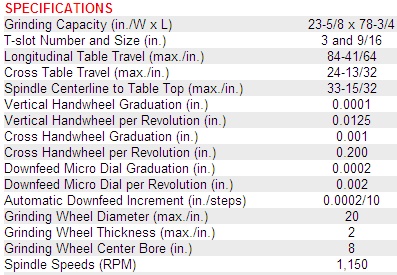

Kent USA 24"x80" Surface Grinder

Proprietary Equipment

Southern Prestige Industries has developed a number of machines internally - many of which are used in our Precision Perforated Products division.

While we certainly take advantage of the latest technological advances the industry offers 'off the shelf', our ability to develop and build proprietary production

equipment internally has proven time and again to benefit our customers.