Specialty Precision Perforating®, LLC

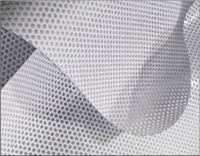

Specialty Precision Perforating (SPP) is a prime global source for

soft goods perforation. Our slogan is, “We perforate for the

HOLE world!” SPP has unparalleled expertise

in both micro and standard perforation. We convert various

materials for large international corporations, as well as for

smaller companies according to our customer needs.

Specialty Precision Perforating (SPP) is a prime global source for

soft goods perforation. Our slogan is, “We perforate for the

HOLE world!” SPP has unparalleled expertise

in both micro and standard perforation. We convert various

materials for large international corporations, as well as for

smaller companies according to our customer needs.

SPP perforates the majority of the vinyl used throughout the world

for creating one-way vision images. In fact, SPP perforated several products with one-way graphic imagery used

extensively at the 2008 Summer Olympics in China. We

are widely known as the foremost provider of material for perforated graphic

imagery used throughout the racing industry, with products

associated with the NASCAR Sprint Cup Series, Nationwide

Series, and Craftsman Truck

Series, as well as the IndyCar Series.

This

image gallery

illustrates use of our perforated films in applications that create

valuable advertising space on one side, while preserving a clear

view from the other.

This

image gallery

illustrates use of our perforated films in applications that create

valuable advertising space on one side, while preserving a clear

view from the other.

In addition to

material for use in graphic imagery, SPP micro-perforates a wide array of

other products, i.e., acoustical panels and surfaces, filtration

products, food packaging products, clean-room components, medical

products, and many more. These numerous

products function to filter, absorb, and/or diffuse various forms of

energy and/or media. Our many different perforated products also

function to enclose, divide, decorate, and/or ventilate physical

entities. Perforated one-way imagery and many other technologies

pioneered by SPP have patents in place, as well as some patents

pending.

In addition to

material for use in graphic imagery, SPP micro-perforates a wide array of

other products, i.e., acoustical panels and surfaces, filtration

products, food packaging products, clean-room components, medical

products, and many more. These numerous

products function to filter, absorb, and/or diffuse various forms of

energy and/or media. Our many different perforated products also

function to enclose, divide, decorate, and/or ventilate physical

entities. Perforated one-way imagery and many other technologies

pioneered by SPP have patents in place, as well as some patents

pending.

We have thirty years of experience in perforating. The

combination of our perforating experience, the talents of our

people, and our company resources enables us to build our own

perforators. Thus, SPP has the unique ability to develop new

processes and products to meet specific customer requirements.

Customer satisfaction is the focus at Specialty Precision Perforating. We achieve this priority through consistent on-time delivery of cost-effective, quality products. Expert inventory control and JIT delivery are hallmarks of the service we provide. Other services like our Total Inspection Process enable our customers to eliminate costs on their end with quality they can count on.

Our parent company, SPI was designated one of the fastest growing private companies in America,

ranking as one of the top 100 manufacturing companies in the

Inc. 5000 for 2008 and 2009.

The Wall Street Journal Business Center film, "A Vision to Succeed"

offers further insight into our unique capabilities.

Stay up to date with progress at Specialty Precision Perforating through

VISIONS, our quarterly newsletter.

CAPABILITIES

Machines/Tooling

SPP has complete engineering (CAD, CNC, & EDM) capabilities

in-house to design, build, and maintain all of the machinery and

tooling required to meet customer expectations for soft-goods

perforated products. We build precision tools and machines using

advanced CNC programs. Progressive, high-speed computer controlled

presses perforate holes and patterns to customer specification. Our presses

perforate material thickness from .001" to .030", hole diameters

from .015" to 1.00" and widths up to 72

inches.

Materials

Materials

Paper, Plastic, Vinyl, PVC, Polyester, Fabrics,

Non-Wovens, Multi-ply laminates, film, and special customer

materials

Processing

Stamping: Die cutting, Cut-Out, Embossing

Tear Perforations: 36" wide, any distance between tears

Slitting: Before or after perforating

Sheeting: 36" wide, any length

Rewinding: Any core size, widths to 54", 40" OD

Laminating: widths to 60"

Packaging/Shipping

We package and ship to customer specification. Our packaging capabilities

include shrink-wrap, palletization, custom box, and virtually any other

configuration you can imagine... all designed to ensure zero loss of quality

in transit. If you prefer for us to arrange shipping, we have secured

advantageous rates with most major carriers, and have daily scheduled pickups.